Non-Destructive Testing (NDT)

At KWAN-TEK, we believe that inspecting the integrity of structures and materials should never mean compromising them. That’s why we are redefining non-destructive testing (NDT) with state-of-the-art quantum sensing. Our innovative quantum sensor technology based on NV-diamond magnetometry opens new pathways to detect flaws, cracks, monitor critical assets, and secure your operations — all without damage and with minimal disruption.

A quantum leap in inspection technology

Traditional inspection methods have long been the backbone of industrial quality assurance, but they often come with limitations: partial detection, surface-only results, intrusive sampling, or high maintenance costs. Kwan-tek’s quantum NDT solutions break through these barriers by enabling deep, precise, and non-invasive inspections.

At the core of our approach lies our mastery of NV center diamonds — a unique quantum property that turns diamond into a powerful sensing medium. When coupled with our proprietary optical readout techniques, these sensors can detect even the faintest magnetic signatures left by hidden cracks, corrosion, or stress points within metal and composite structures.

Imagine inspecting an aircraft fuselage or a pressure vessel with high confidence that no internal fault will go unnoticed — and doing so without dismantling or damaging a single component. That’s the power of quantum sensing applied to NDT.

How quantum diamond sensors make the invisible visible

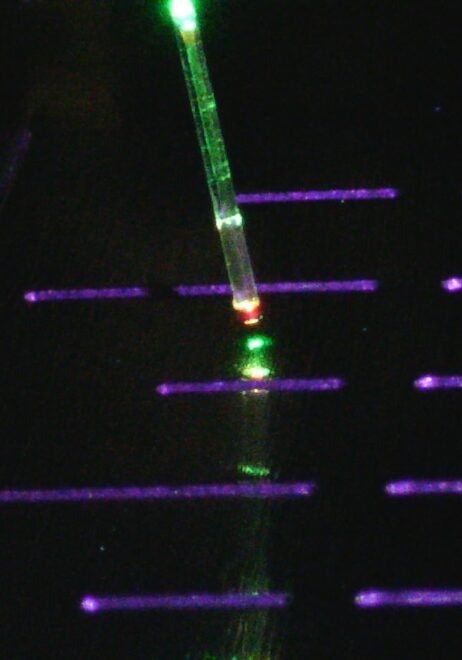

Our Low-Field NV Magnetometer is a game changer for industries seeking higher inspection accuracy and data reliability. Here’s how it works: the NV centers inside the diamond respond to local magnetic fields when illuminated by a laser and excited by microwaves. By analyzing the photoluminescence emitted, we can map variations in the magnetic field with exceptional spatial resolution — providing engineers with information about defects that would otherwise stay hidden.

This means you can detect sub-surface cracks or weld imperfections up to several millimetres deep — even when they are hidden under protective coatings, layers of paint, or within complex shapes where standard probes can’t reach.

Our technology is non-contact, adaptable, and robust enough to deliver consistent results in harsh environments where conventional sensors lose accuracy.

Quantum diamond sensors measure tiny changes at the microscale, ensuring that smallest defects do not escape detection.

Our solution provides quantitative, offering richer insights for better maintenance decisions.

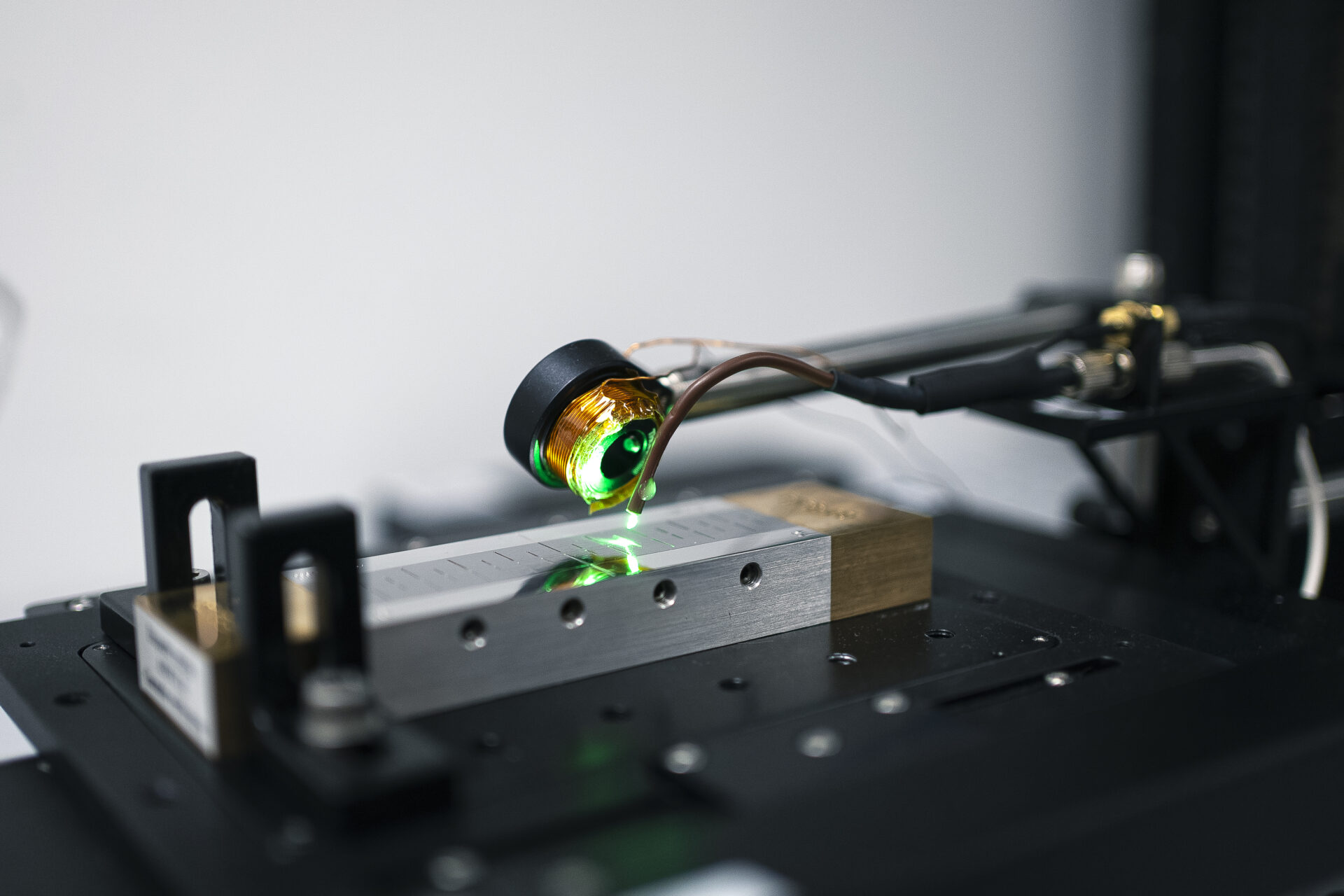

The compact design of our NV magnetometer probes allows them to fit easily into robotic arms, handheld inspection devices, or fully automated lines.

Diamonds don’t just enable quantum sensing — they make our sensors exceptionally resistant to heat, pressure, and wear. This ensures stable measurements year-round.

Early detection means fewer unexpected failures, optimized maintenance schedules, and better resource allocation — translating to significant savings over time.

Our sensors can be deployed remotely, even in difficult or hazardous locations. Inspections can be performed safely without exposing operators to risks.

Fields of application

KWAN-TEK’s quantum NDT solutions are trusted in sectors where failure is not an option:

- Aerospace & Defence — Inspect fuselages, wings, turbine blades to detect hidden fatigue before it becomes a threat.

- Energy, Oil & Gas, Nuclear — Monitor pipelines, pressure vessels, and critical infrastructure continuously, even in extreme temperatures or high-radiation zones.

- Hydrogen & Emerging Clean Tech — Validate the integrity of tanks and high-pressure systems designed for next-generation fuels.

- Metallurgy & Advanced Manufacturing — Inspect welds, joints, and metal structures without halting production — ensuring the highest safety and compliance standards.

Our Low-Field NV Magnetometer: a closer look

Compact yet powerful, the KWAN-TEK Low-Field NV Magnetometer uses a fiber-optic probe to measure the magnetic field generated by imperfections or stress concentrations within a material. Its small footprint and fast measurement capability make it ideal for integration into inline inspection stations or mobile inspection kits.

Key benefits include:

- Surface and subsurface defect detection up to 10 mm deep in metals (depending on material properties).

- Adaptability to complex geometries, remote areas, or harsh conditions.

- Optical readout that eliminates interference from temperature fluctuations or mechanical vibrations.

At KWAN-TEK, we don’t just deliver hardware — we co-create solutions with our partners. Our R&D team works closely with aerospace engineers, energy companies, and research institutions to adapt our quantum sensing systems to unique operational contexts. This collaborative mindset ensures that every deployment meets the highest performance and safety standards.

Ready to see what quantum sensing can do for your inspections?

Let’s talk about how KWAN-TEK can help you strengthen safety, reduce costs, and push the limits of what’s possible in non-destructive testing.